by admin | May 13, 2021 | News

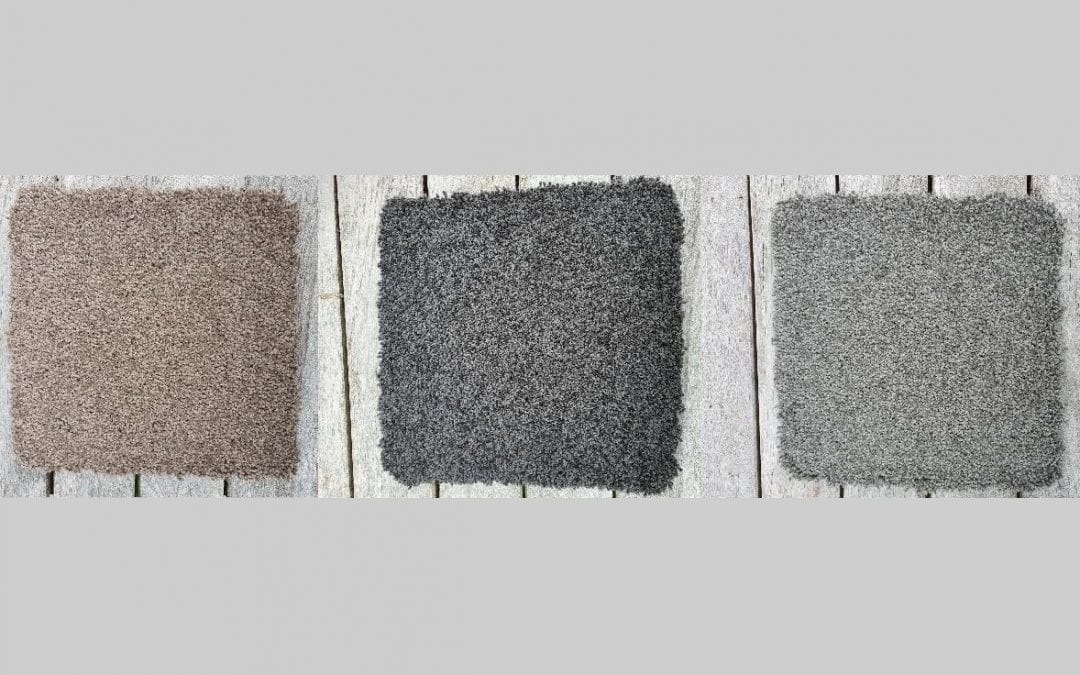

We are calling for expressions of interest in out next shipment of carpet due in approximately 4 months. Carpet The carpet has been made to the highest standards. We have received samples off the bulk, we are delighted with them. Those of you whose wool is in any of...

by admin | Feb 12, 2021 | News

Carpet The bulk run of our carpet has been made and will be in our hands ready for distribution on the 23rd of February 2021. The carpet has been made to the highest standards. We have received samples off the bulk, we are delighted with them. Those of you whose wool...

by admin | Feb 22, 2020 | News

We recently appeared in the Southland Times… You can read the article by following this link: Click Here

by admin | Jan 20, 2020 | News

Wool co-op’s gear catches retailer’s eye Wednesday, 15 January 2020 – By Brent Melville Local Dunedin startup wool network AgMatch has attracted the eye of one of Australia’s biggest retail groups, Frontline. The online selling group — owned by about 650 farmers...